Case Studies

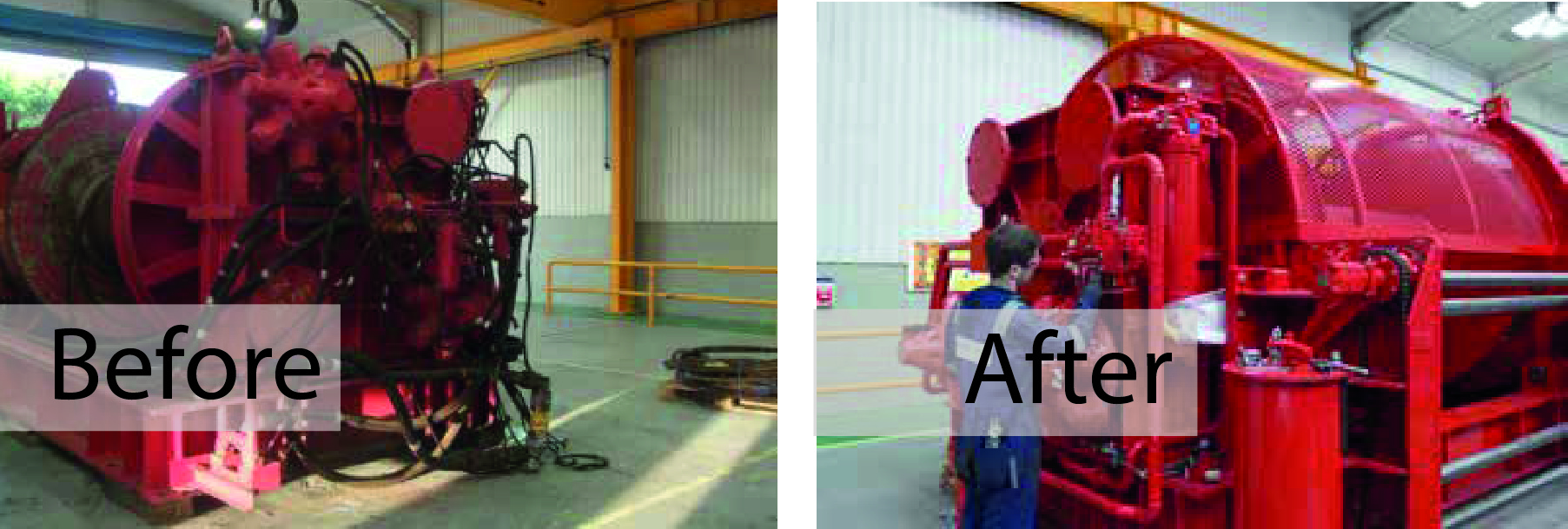

Complete rebuild of four 75te Double Drum Mooring Winches.

SCOPE OF WORK:

• Full strip down, shot blast and rebuild of winches • All parts shot blasted and repainted to original specification • Diesel engine and drive system overhaul • New control system designed and safety guards fitted • MPI…

Refurbishment and upgrade of an 80te SWL Pull-in Winch following comprehensive on-site winch survey.

SCOPE OF WORK

• Winch drum modifications to modernise design under DNV 2.22 rules and GAP analysis produced. • Upgrade of brake system to a true mechanical auto fail safe brake system •…

Complete rebuild of four Heavy Mooring Winches.

SCOPE OF WORK

• Drive train and braking systems fully reverse engineered and rebuilt • Bespoke spooling gear manufactured to suit over spooling • FAT tested to ACE specifications

We were awarded the task of rebuilding eight Skagit anchor winches onboard the John Shaw drilling rig.

All parts and components of the winches needed to be cleaned, blasted and painted.

Brake bank linings were removed, inspected, shot blasted and relined.

New bull gears and drive pinions were…

Complete refurbishment of four 100te BOP Hoist Units.

SCOPE OF WORK

• Full strip down, shot blast and rebuild of hoists using OEM components • All parts shot blasted and repainted to original specification • MPI and NDT of all critical lift points • FAT tested to OEM specifications

The 500te RDS was designed and manufactured at ACE Winches facilities. The product range includes a 200te and a 400te RDS which were developed for high tension spooling and have been used in the deployment and recovery of subsea products such as umbilicals, risers and flow lines, flexible…

ACE Winches manufacture a range of standard and bespoke drum winches, available in single or double drum configurations. Drum winches are designed to be utilized for hoisting, deployment, mooring and general pulling applications and, depending on the size and power requirement, can be…

The complete project will see an existing floating production storage and offloading (FPSO) vessel replaced with a larger, purpose-built FPSO to accommodate new field tie-ins. The development of additional wells and the installation of new subsea infrastructures in neighbouring fields are also…

A 10 point mooring spread was required to lay 3 export cables from Greater Gabbard Wind Farm to the Suffolk coast. Greater Gabbard is a 504MW wind farm on sandbanks 23km off the coast.

In addition to cable lay operations the ACE Winches system was used on board…

Various hire winch packages supplied to the UR101 Barge. The vessel is a pontoon equipped for cable lay work.

ACE Winches equipment included a pull ahead winch package and constant tension cable plough winch packages used in cable lay operations.

SCOPE OF SUPPLY ACE…